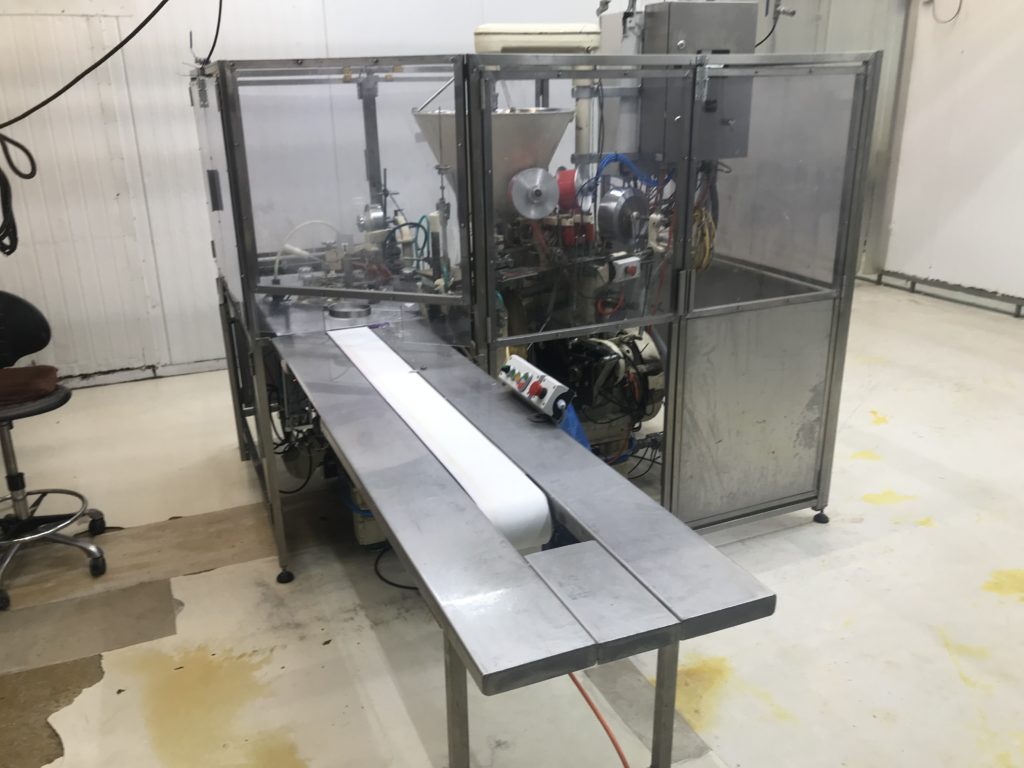

2 PROCESSED CHEESE CONDITIONING MACHINES

1- KUSTNER YH 15 GR PRODUCT

This machine was overhaul by Brenet in 2008 (FR)

- The central gear box was overhauled in 2020 with replacement of the brass bush with bearings and fitting of a seals

- Tear tape in Y shape on the step table

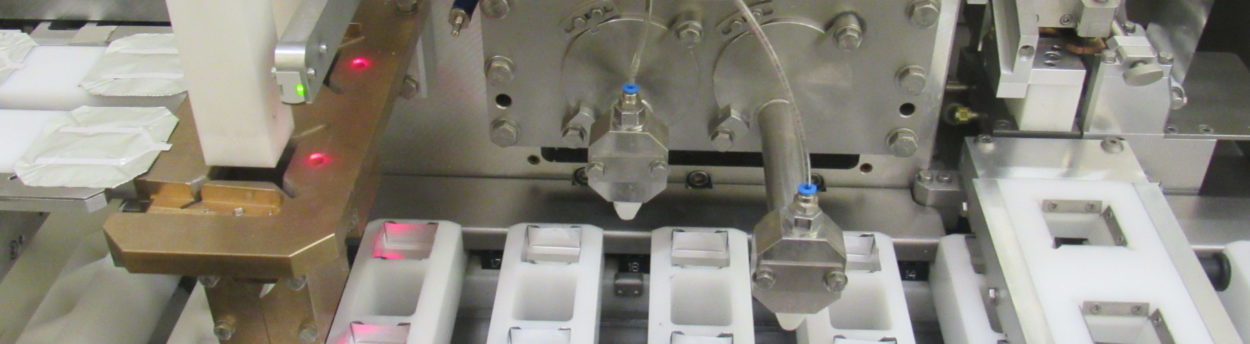

- Plunger in FDA materials with precise anti-rotation guidance.

- Cheese motorized mixing arm

- Filling nozzle with closing valve and air pressure drop stop

- Grouping strap

- Vacuum exit arm

- Display on PLC

- Step by step conveyor belt (1,5m),

shell and cover missing security - Cycling stop, welding locker, end of rolls security

- Door protect available with safety locking

- Automatic central lubrication (Lincoln)

- Cheese weight adjustment near the conveyor

2- KUSTNER YH 20 GR PRODUCT

This machine was overhaul by PPML (GB)

- Mechanical unwinder pairing with foil step arm’s

- Tear tape in X shape on the step table

- Fix plounger ( unadjustable plounger arm’s)

- Sleepiring shell locker (on plounger)

- Cheese motorized mixing arm

- Mechanical filling nozzle with closing valve

- Pneumatic exit arm on conveyor belt

- Display on PLC with product counter

- Step by step conveyor belt (1,5m), shell and cover missing security

- Cycling stop, welding locker, end of rolls security

- Door protect available with safety locking

- Automatic central lubrication (Lincoln)

- Cheese weight adjustment near the conveyor

Other photos and informations on request…